In the global trend of resource recycling, the disposal of waste tires has evolved from simple volume reduction to high-value utilization. The rubber granulation and fiber removal system, a core component of waste tire recycling, is transforming “black pollution” into “black gold.” This article will comprehensively explore the system’s principles, equipment composition, process flow, and application prospects.

The rubber granulation and fiber removal system is an integrated tire recycling equipment that converts entire waste tires into high-purity 1–5 mm rubber granules through a complete process of shredding—separation—granulation, while simultaneously achieving efficient separation and recovery of nylon fibers.

Core Values:

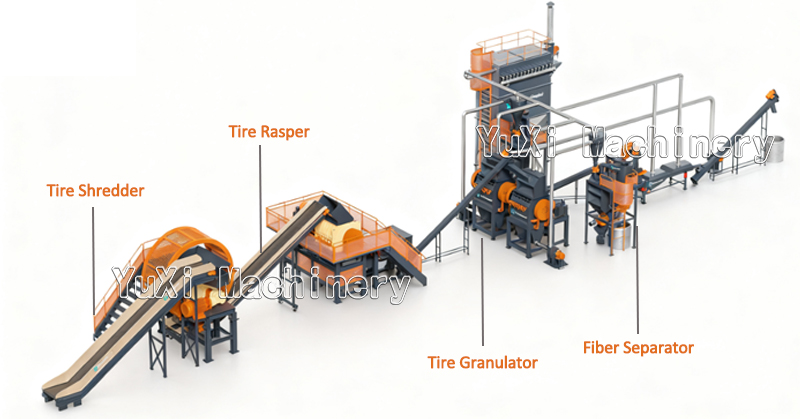

1.Tire Shredder

2.Tire Rasper

3.Tire Granulator

4.Fiber Separator

5.Pulse Dust Collection System

1.Intensive Shredding Stage

Waste tires (passenger car, truck, etc.) first enter the tire shredder, where they are shredded into 50–150 mm rubber blocks under strong shear force, preparing them for subsequent fine separation.

2.Steel Wire Separation Stage

Rubber blocks enter the tire rasper, where rubber and embedded steel wires are completely separated through high-speed rotation and physical friction. Separated steel wires can be directly sold as high-quality scrap steel.

3.Fiber Removal Stage

After steel wire separation, rubber blocks still contain small amounts of fibers. The fiber separator effectively removes these lightweight fibers using air separation or vibratory screening, ensuring the purity of rubber raw materials.

4.Fine Granulation Stage

Purified rubber blocks are fed into the granulator, where they are extruded and die-cut into uniformly sized, clean 1–5 mm rubber granules. This stage is critical for determining the final product quality.

5.Dust Collection and Packaging Stage

The pulse dust collection system controls dust throughout the process to ensure a clean workshop environment. Finished rubber granules are screened and packaged according to customer requirements.

1.High Efficiency and Yield

Automated production line design provides strong processing capacity and continuous stable operation, significantly improving recovery efficiency.

2.Pure Products

Multi-stage separation process (steel wire separation + fiber separation) ensures the production of high-purity, low-impurity, and high-market-value rubber granules.

3.Fast Return on Investment

Converts waste tires into directly marketable rubber granules and steel wires, creating sustainable economic benefits.

4.Durability

Core components of the equipment are made of high-strength, wear-resistant materials, capable of withstanding the harsh conditions of tire shredding, ensuring a long service life.

5.Environmental Compliance

Fully enclosed dust collection throughout the process; emission indicators exceed national standards, meeting the strictest environmental requirements.

Processable Raw Materials:

Final Products:

Application Areas:

With the growing global emphasis on environmental protection and resource recycling, the waste tire recycling industry is entering a period of rapid development. The rubber granulation and fiber removal system, as a key technology for high-value utilization of tires, continues to see increasing market demand.

Economic Benefit Analysis (based on annual processing of 10,000 tons of waste tires):

1.Technological Innovation Directions

2.Industrial Chain Extension

3.Global Layout

With the increase in vehicle ownership in developing countries, demand for waste tire disposal will grow rapidly, shifting market focus to emerging markets.

The rubber granulation and fiber removal system is not only a technological innovation but also key to the resource utilization of waste tires. It transforms “black pollution” into “black gold,” making significant contributions to the circular economy and sustainable development. With continuous technological progress and market maturation, this system will undoubtedly play an increasingly important role in future waste tire recycling.