Waste tire recycling is a complex process, but with the right system, you can transform “black pollution” into valuable resources. In this guide, we’ll walk you through how to set up and optimize a rubber granulation and fiber removal system to maximize your recycling efficiency.

A rubber granulation and fiber removal system is a comprehensive solution designed to:

Output materials: Clean rubber granules, recycled steel wire, and separated fibers.

Capacity: 1,100–22,000 lbs (500–10,000 kg) per hour, depending on the model.

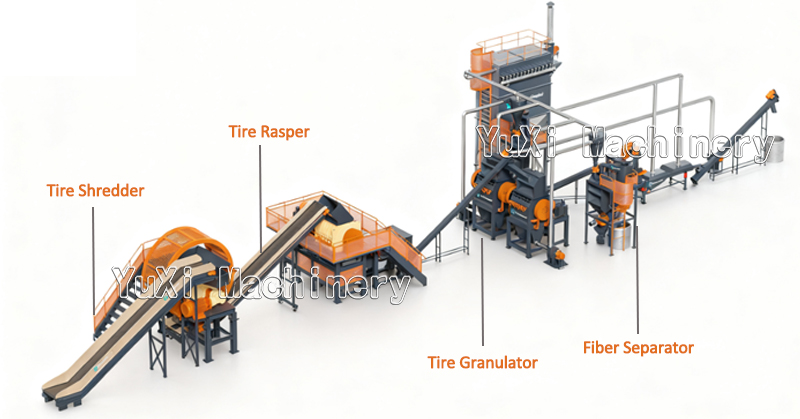

Start by feeding whole tires into a tire shredder. This machine breaks down passenger car and truck tires into 2–6 inch (50–150 mm) rubber chunks.

Key features of an effective tire shredder:

Next, feed the shredded rubber chunks into a tire rasper. This machine uses high-speed rotation and physical friction to separate steel wire from the rubber matrix.

For best results:

After steel wire separation, the rubber still contains small amounts of light fibers. Use a fiber separator to remove these using air separation or vibratory screening.

Tips for efficient fiber removal:

Finally, feed the purified rubber into a tire granulator. This machine uses extrusion and die-cutting to produce uniform 0.04–0.2 inch (1–5 mm) rubber granules.

To optimize granulation:

A well-designed rubber granulation system offers several key benefits:

The system can process a wide range of materials, including:

End products find use in:

A rubber granulation and fiber removal system is a game-changer for waste tire recycling. By following these four key steps, you can significantly enhance your recycling efficiency, reduce waste, and create valuable products from what was once considered pollution.