In the profound transformation of global green transition, efficient resource recycling has become a core dimension for measuring industrial competitiveness. A core equipment integrating precision mechanical design and intelligent control technology is quietly reshaping the industrial pattern of solid waste resource utilization. With its ultimate separation efficiency, it breathes new life into previously discarded composite materials, becoming a key force driving the implementation of a circular economy. Today, we will conduct an in-depth analysis of this “invisible champion” in the field of resource regeneration from three perspectives: technical deconstruction, scenario applications, and value empowerment.

The core competitiveness of this equipment stems from the in-depth integration of material properties and mechanical movement. Every design detail is aimed at achieving the separation goals of “efficiency, purity, and stability.”

1.Material Adaptation Conquering Composite Challenges

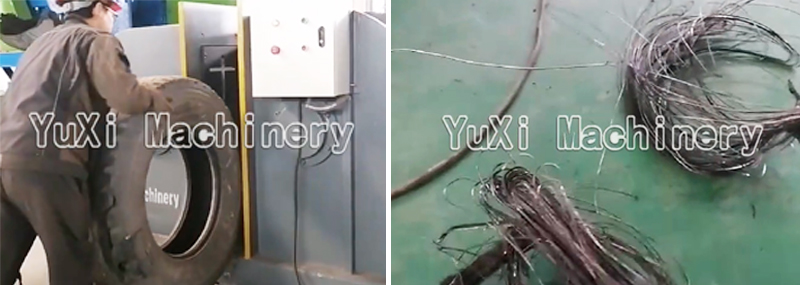

It accurately matches processing needs based on the characteristics of high-toughness composite waste: whether it is rubber products with metal skeletons, fiber-reinforced plastic components, or multi-layer composite industrial scraps, it can achieve efficient separation through customized processing solutions. The key lies in the precise calculation of the physical properties (hardness, toughness, adhesion) of different materials, ensuring that the original performance of the target recycled materials is not damaged during the separation process.

2.Structural Innovation Precision Control of Dual-Drive Coordination

The equipment adopts a dual-drive coordinated design, with core executive components made of AISI 4140 high-strength wear-resistant alloy, reinforced through multiple heat treatment processes to withstand long-term high-intensity operations. Through the linkage control of servo motors and hydraulic systems, it achieves a displacement accuracy of 0.05mm, ensuring uniform force during separation and avoiding material loss caused by local excessive extrusion. At the same time, the built-in intelligent sensing module monitors load changes in real time and automatically adjusts operating parameters, ensuring the separation purity remains stable above 99.5%.

3.Intelligent Upgrade Full-Process Automated Control

Modern versions have achieved full-process intelligent upgrades: the automatic feeding system accurately locates materials through visual recognition technology, and robotic arms cooperate to complete grabbing and placing; the central control system integrates PLC and industrial Internet of Things modules, capable of storing more than 200 types of process parameters and supporting remote monitoring and fault early warning; the energy recovery device converts kinetic energy generated during operation into electrical energy, saving more than 40% energy compared to traditional equipment, with motor power ranging from 15-75kW, significantly reducing long-term operating costs.

Its applications have long exceeded a single recycling scenario, becoming a resource conversion hub connecting multiple industries and providing customized solutions for enterprises of different sizes and fields.

1.Applicable Fields From Industrial Waste to Domestic Waste

Its processing scope covers various types of composite waste:

2.Process Connection Building a Complete Resource Cycle Chain

In the recycling industrial chain, it is in the core conversion link, connecting front-end crushing and back-end reprocessing:

This full process of “crushing → separation → reprocessing” increases the comprehensive recovery rate of composite waste to over 98%, far exceeding the 60% of traditional recycling models.

3.Customized Solutions Adapting to the Needs of Enterprises of Different Sizes

The value of this equipment has long surpassed the scope of a “recycling tool,” becoming an important support for enterprises to achieve green transformation and enhance core competitiveness.

1.Economic Value From Cost Burden to Profit Growth Point

2.Environmental Value Quantified Green Contributions

3.Industrial Impact Promoting Industrial Standardization and Upgrading

Its widespread application is driving the resource recycling industry towards standardization and efficiency:

When selecting equipment, it is necessary to comprehensively evaluate technical parameters, operating costs and long-term value to avoid blind investment.

1.Core Parameters Three Key Indicators

2.Development Trends Three Technical Directions

3.Investment Return Rational Calculation of Expected Benefits

Taking a piece of equipment with a daily processing capacity of 20 tons as an example:

This equipment is not only a crystallization of technological innovation but also a vivid practice of the circular economy concept. With its precision engineering design, it breaks the technical bottleneck of composite waste recycling; with its wide-ranging scenario applications, it builds a resource circulation hub; with its significant economic and environmental benefits, it opens up a new path for enterprises to achieve green development.

In today’s in-depth advancement of “dual carbon” goals, investing in such an efficient and intelligent resource separation equipment is no longer a simple cost input, but a strategic layout for future industrial competitiveness. It will help enterprises seize opportunities in the green transformation wave, achieve their own development while contributing to the sustainable utilization of global resources.

If you want to learn more about customized solutions, technical parameters or investment calculation details of the equipment, please feel free to contact us to jointly explore the unlimited possibilities of resource circulation.