As scrap tire recycling shifts from “rough shredding” to “high-value resource utilization,” the rubber granulation and fiber removal system has transformed the value of scrap tire recycling—it not only converts scrap tires into uniform, clean rubber granules but also precisely separates fibers and steel wire, ultimately producing “high-purity rubber raw materials + recycled metal + recoverable fibers.” This makes it a benchmark piece of equipment for “precision recycling” in the circular economy.

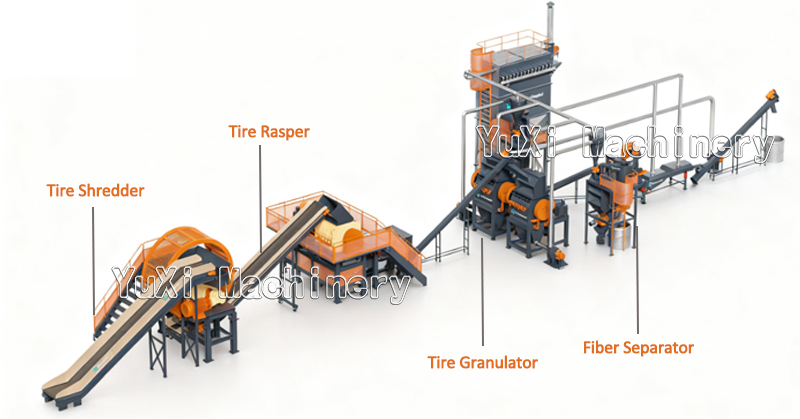

This is an integrated deep-processing system for scrap tires, consisting of core equipment like tire shredders, tire raspers, and tire granulators, paired with zig-zag air separators and pulse dust collection systems. It processes scrap tires into 1–5mm clean rubber granules while precisely separating fibers, steel wire, and rubber, enabling “full resource utilization” of all tire components.

Traditional scrap tire recycling often stops at “coarse shredded material,” but this system “disassembles, purifies, and refines” scrap tires—the final rubber granules can be directly used in high-end rubber product manufacturing, completely shedding the label of “low-value waste.”

The system’s adaptability covers most rubber-fiber-metal composite products, with core processing materials including:

Whether it’s old tires from household cars or heavy-duty rubber products retired from industrial scenarios, any item containing rubber, fiber, and steel wire can be processed to a standardized, precision level using this system.

The rubber granulation and fiber removal system’s full process is a continuous, automated sequence of “shredding → separation → purification → granulation,” with every step focused on maximizing product purity and resource utilization:

1.Powerful Shredding: Break Whole Tires Into Base Granules

Scrap tires (passenger/truck tires) are first fed into a Tire Shredder—equipped with a 100HP (≈75kW) NEMA-standard motor, the machine uses strong shearing and compression to shred whole tires into 50–150mm rubber chunks. This step not only reduces tire volume but also loosens the bond between rubber, steel wire, and fibers, preparing the material for subsequent precision separation.

2.Steel Wire Separation: Fully Separate Rubber and Steel Wire

The shredded rubber chunks enter a Tire Rasper—its core components are made of AISI D2-grade alloy. Through the combined action of high-speed rotation and physical friction, embedded steel wire is completely stripped from the rubber. The separated steel wire is collected separately and can later be sold directly as recycled metal raw material meeting ISRI standards.

3.Fiber Removal: Deeply Purify the Rubber

After steel wire separation, small amounts of fiber remain in the rubber chunks. The mixture then enters a Fiber Separator: using air separation or vibratory screening (meeting ASTM screening precision standards), the system efficiently removes lightweight fibers from the rubber, ensuring the cleanliness of the subsequent rubber raw material. This step is critical to enhancing rubber granule value, as it prevents fiber residue from impairing the performance of rubber products.

4.Precision Granulation: Process Clean Rubber Into Standardized Products

The purified rubber chunks are fed into a Tire Granulator, where extrusion and die-cutting processes convert them into 1–5mm uniform, high-purity rubber granules (meeting EPA recycled rubber raw material standards). Meanwhile, the separated steel wire is collected and packaged in bulk. The system ultimately produces two high-value products: “rubber granules + recycled steel wire.”

Compared to traditional recycling equipment, this system’s advantages span product value, recycling efficiency, and long-term operation—directly determining the profitability of recycling projects:

1.High Efficiency & Capacity: Automated Production, Maximum Throughput

Designed as a fully automated production line, the system operates continuously and stably while significantly boosting recycling efficiency—capacity reaches 550–11,000 lbs/hour, making it suitable for both small-to-medium recycling plants and large-scale recycling projects.

2.Pure Products: Multi-Stage Separation for High-Value Raw Materials

Through “steel wire separation + fiber separation” multi-stage sorting, the system ensures high final product purity:

3.Fast Payback: Turn Scrap Tires Into Directly Marketable Products

The system’s core value lies in converting “low-value scrap tires” into “directly salable rubber granules + recycled steel wire”—both products are in high demand by downstream industries, enabling rapid capital turnover and creating sustainable economic benefits for recycling enterprises.

4.Durability: Robust Components for Harsh Operating Conditions

The system’s core components are made of high-strength, wear-resistant materials, allowing them to withstand the harsh conditions of scrap tire shredding. This drastically reduces maintenance frequency and replacement costs, ensuring long-term stable operation and extending the equipment’s service life.

Driven by European and American circular economy policies and carbon reduction goals, the focus of scrap tire recycling has shifted from “processing volume” to “product value”—and the rubber granulation and fiber removal system is the core enabler of this transformation:

It turns scrap tires from an “environmental burden” into “multi-category recycled resources,” solving the environmental pollution problem of scrap tires while providing low-cost raw materials to the rubber and metal processing industries. For recycling enterprises, this system not only improves resource utilization but also unlocks higher profit margins through high-value products, achieving a true “win-win for environmental protection and economic returns.”