With over 1.5 billion scrap tires generated globally each year, resource recycling of this “black waste” is no longer an option—it’s a necessity for environmental protection and industrial upgrading. Efficient separation of rubber and steel wire in tires is the core link that determines recycling value: traditional manual sorting is inefficient and wasteful, but the tire wire separation system has emerged as a solution, directly connecting scrap tires from “waste” to “high-value recycled resources” across the entire industry chain, making it a “hardcore piece of equipment” in the circular economy.

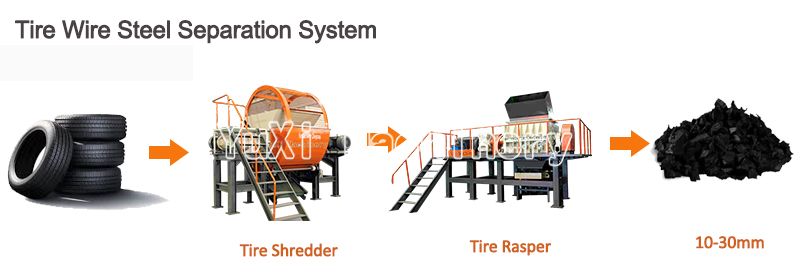

This is the core processing system for scrap tire recycling, consisting of equipment like tire shredders and tire wire separators. Through an automated process of “powerful shredding + high-efficiency sorting,” it processes entire scrap tires into high-purity steel wire and uniformly sized rubber granules (10-30mm), ultimately achieving complete separation and resource utilization of the tire’s two core components (rubber and steel wire).

Simply put, it’s an “industrial magician” that turns “dirty scrap tires” into “directly marketable rubber raw materials + recycled steel wire,” completely solving the industry pain points of “incomplete separation and low product value” in traditional recycling.

The system’s durability and adaptability make it highly efficient at handling nearly all common types of scrap tires:

Whether it’s old tires replaced from household cars or heavy-duty tires retired from engineering scenarios, any tire containing rubber and steel wire can be processed to a standardized level by this system.

Workflow: 4 Steps to Go From Scrap Tire to Recycled Resource

The tire wire separation system’s full process consists of 4 automated, continuous core stages: Feeding & Shredding → Initial Separation → Magnetic Sorting & Purification → Finished Product Output:

Compared to traditional recycling methods, the system’s advantages span separation efficiency, product value, and operating costs—directly determining the profitability of recycling projects:

1.Over 99% Separation Rate: Near “Zero Waste” Resource Utilization

Using unique separation technology, the system achieves over 99% separation rate between rubber and steel wire—meaning almost all rubber and steel wire can be recovered separately, eliminating “mixed material waste” and maximizing the resource value of every scrap tire.

2.High-Quality Finished Products: Direct Access to High-Value Downstream Markets

3.High Efficiency & Energy Savings: “High Capacity” With Low Energy Consumption

With scientific power configuration and streamlined process design, the system achieves extremely high processing efficiency while maintaining low energy consumption: capacity reaches 550-16,500 lbs/hour—small systems meet the needs of medium and small recycling plants, while large systems support the capacity requirements of large-scale recycling projects.

4.Continuous Automation: Reduce Labor Costs & Operational Risks

The entire process requires no manual intervention; from feeding to finished product output, everything is automated: on one hand, it reduces the high cost of manual sorting (traditional manual sorting takes over 30 minutes per tire); on the other hand, the equipment meets OSHA safety standards, avoiding safety risks like scratches and crush injuries from manual operation, making recycling project operations more stable and worry-free.

Driven by European and American circular economy policies and carbon reduction goals, scrap tire recycling has shifted from “hazard-free disposal” to “high-value resource utilization”—and the tire wire separation system is the “core pillar” of this transformation:

For recycling enterprises, this system not only improves processing efficiency and reduces operating costs but also significantly boosts project profit margins through the dual output of “high-purity rubber granules + recycled steel wire.” For the entire industry, it turns scrap tires from an “environmental burden” into “renewable resources,” driving rubber, steel, and other industries to form a “resource-product-waste-recycled resource” closed loop and supporting green industrial upgrading.