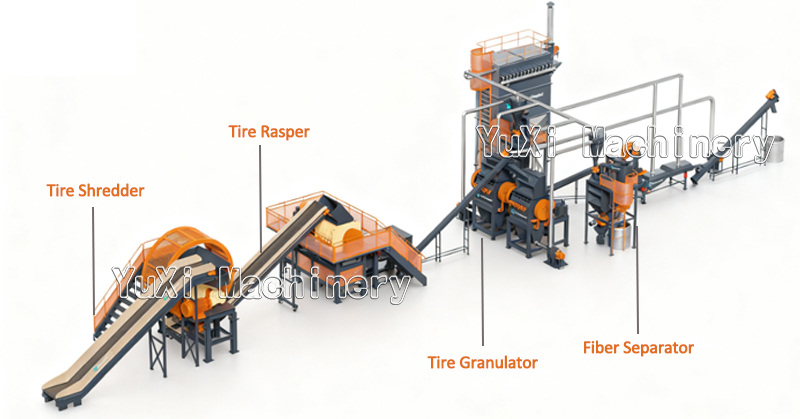

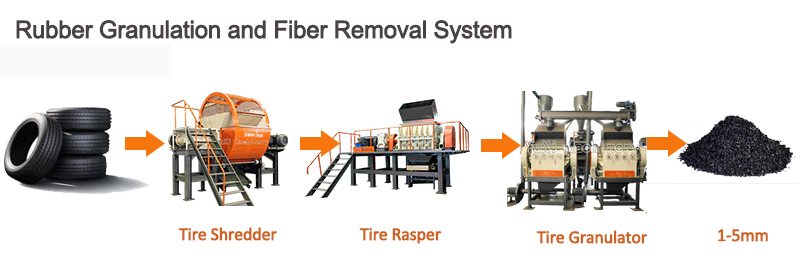

Main Machines: tyre shredder,tyre rasper, tyre granulator machine

Output Material: 1-5mm rubber crumbs, nylon fiber, steel

Capacity: 500~10,000 kg/h

The system includes rubber granulator, zig-zag air separator and pulse dust removal system. It can process rubber granules into 1-5 mm size. During this process, the majority of the nylon fiber is separated and collected. Rubber crumbs can be used for a variety of products such as rubber tiles, running runways, molded products.

Step 1: Powerful Shredding

Whole scrap tires (passenger and truck tires) are initially shredded by a tire shredder, shredding them into rubber chunks sized 50-150mm, preparing them for subsequent fine separation.

Step 2: Wire Separation

The rubber chunks enter the tire wire separator, where high-speed rotation and physical friction thoroughly and cleanly separate the rubber from the embedded steel wires.

Step 3: Fiber Removal

After the steel wires have been separated, the rubber chunks still contain a small amount of fiber. The fiber separator uses air separation or vibrating screening to effectively remove these lightweight fibers, ensuring the purity of the rubber material.

Step 4: Fine Granulation

The purified rubber chunks are fed into a granulator, where they are extruded and cut through a die to produce uniform, clean rubber granules sized 1-5mm. The separated steel wires are also collected and packaged.

Passenger car tires

Truck tires

Other rubber products (adjustable depending on equipment configuration)

End products

High-purity rubber granules (1-5mm)

Clean recycled steel wire

1.High Efficiency and High Productivity: The automated production line design provides powerful processing capacity and continuous, stable operation, significantly improving recycling efficiency.

2.Pure Product: A multi-stage separation process (wire separation + fiber separation) ensures the output of rubber granules with high purity, low impurities, and higher market value.

3.Quick Return on Investment: Converting waste tires into directly marketable rubber granules and steel wire creates sustainable economic returns.

4.Durability: The core components of the equipment are constructed of high-strength, wear-resistant materials to withstand the harsh conditions of tire crushing and provide a long service life.