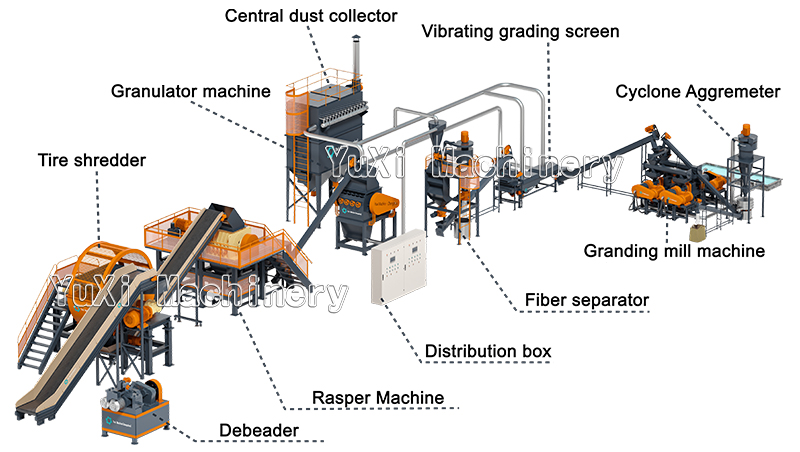

Main Machines: tire shredder, rasper, granulator, fine miller

Output Material: 20~120 mesh powder

Capacity: 500~10,000 kg/h

As a professional manufacturer of scrap tire recycling equipment, we offer a complete suite of automated, highly efficient tire recycling and grinding solutions. This system transforms mountains of scrap tires into high-value-added rubber powder (20-120 mesh) and pure steel wire, achieving 100% resource recycling.

Tire Shredder

Function: Initially shreds entire scrap tires into uniformly sized rubber chunks, preparing them for subsequent fine separation.

Processed Materials: Passenger tires, truck tires, steel-wire radial tires, etc.

Tire Wire Separator

Function: Using unique physical separation technology, completely separates the steel wire from the rubber in the rubber chunks, producing pure rubber granules and clean recycled steel wire.

Processed Materials: Rubber chunks with steel wire after processing in the shredder.

Granulator

Function: Further refines the pure rubber granules after the steel wire is separated, processing them into even finer, more uniform rubber granules. This is an important pre-treatment step before grinding.

Processed Materials: Rubber granules with steel wire removed.

Rubber Pulverizer

Function: The core component of the system, grinding small rubber granules into fine rubber powder of varying finenesses. The finished product fineness can be flexibly adjusted between 20 and 120 meshes according to demand.

Product: High-value rubber powder that can be directly used in downstream industries.

Whole scrap tire → Tire shredder (crushed into pieces) → Tire wire separator (separates rubber from steel wire) → Pelletizer (produces uniform rubber pellets) → Rubber grinder (grinds into fine rubber powder) → Finished product: Pure steel wire & 20-120 mesh rubber powder

1. The production line is water-cooled and temperature-controlled, operating at room temperature to extend the service life of the equipment.

2. The production line adopts modular design, and equipment is configured according to the customer’s production requirements.

3. Advanced technology makes installation, replacement, inspection and maintenance more convenient and safer.

4. We insist on testing each machine before it leaves the factory to ensure good quality and stable performance.