The double-hook wire drawing machine, also known as the tire wire extraction machine, is mainly used to process the crushed radial tire steel wire bead. Its core function is to use two powerful hooks to accurately and forcefully hook and pull out the steel wire embedded in the tire bead, achieving a complete separation of the steel wire and rubber, laying a solid foundation for the subsequent production of high-purity rubber powder.

This equipment is designed specifically for processing tire bead rings (commonly known as “tire rings”) with both sidewalls removed. It is suitable for:

Scrap radial steel wire tire bead rings from various passenger cars, trucks, and construction vehicles.

Semi-finished tire bead rings after initial processing in the tire shredder.

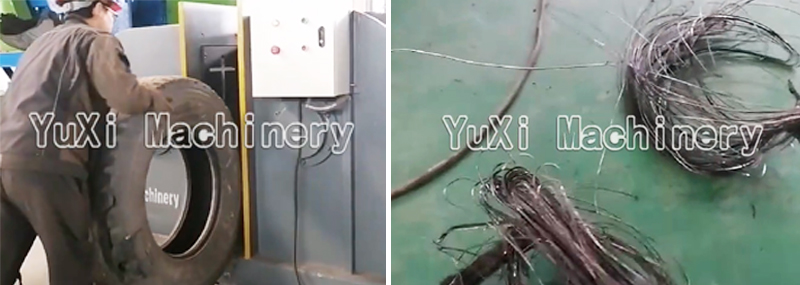

Loading: The operator places the tire rim onto the feed rack.

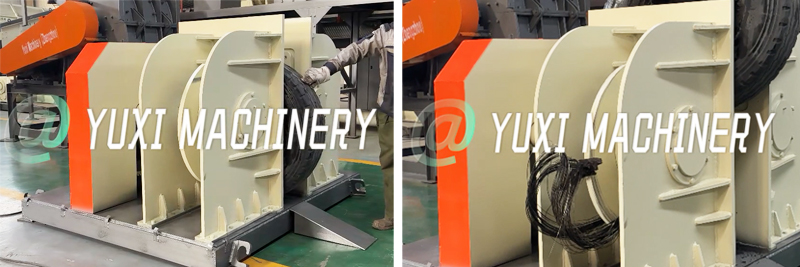

Clamping and Positioning: The equipment automatically clamps and secures the tire rim in place.

Dual Hook Wire Drawing: Two high-strength alloy steel hooks, driven by a hydraulic system, simultaneously cut into the tire rim from both inside and outside, hooking the wire.

Forced Pulling: The hooks move forcefully outward, pulling the entire tire wire intact.

Discharge and Collection: The separated rubber strips fall into a collection hopper, while the pulled, intact wire is collected.

Efficient and Powerful: The unique dual-hook design delivers simultaneous internal and external force, resulting in fast wire drawing speeds, high processing efficiency, and stable output.

Complete Separation: The wire is extracted with a high integrity rate and minimal residue, significantly enhancing the purity and value of the subsequent rubber powder.

Durable: Core components are constructed of high-quality alloy steel and undergo a special heat treatment, ensuring high wear resistance and a long service life.

Automated Operation: The wire drawing process is fully automated, requiring only simple material loading, reducing labor intensity and costs.